With the acceleration of industrialization, the demand for energy is increasing day by day, and oil resources are facing the crisis of exhaustion. Automobile energy conservation has become a global hot issue. At home and abroad, new power transmission systems are being developed and used to improve the economy and power of equipment, reduce energy consumption and protect the ecological environment.

Using accumulator to recover energy can improve the utilization rate of energy, which is an important way to save energy. The accumulator can temporarily store energy, so it can be used to recover a variety of kinetic energy and position potential energy. Specific applications include recovery of vehicle braking energy, recovery of potential energy of construction machinery boom mechanism, recovery of braking energy of hydraulic excavator turntable, recovery of gravity potential energy of oil workover rig and drill pipe falling, recovery of gravity potential energy of elevator descending, etc.

For example, hydraulic elevators are a kind of mechanical equipment widely used in municipal engineering, construction, installation, warehousing, cargo shipment and factory production engineering (in the casting, welding, spraying, handling, assembly and other working places, there are various elevators used as transportation and positioning tools). The driving device of larger elevators generally adopts hydraulic cylinder, which is determined by its structural principle and working characteristics. When the work-piece is lifted by the elevator workbench, the hydraulic cylinder is required to provide driving force, that is, the hydraulic cylinder outputs energy to convert mechanical (hydraulic) energy into potential energy; The potential energy will be released when the elevator workbench carries the workpiece down. If this potential energy cannot be effectively recycled, it will cause energy waste. This kind of energy waste is not serious for small elevators, but it is very serious for machinery that needs to work frequently due to large load and lifting height. For such machinery, energy storage devices should be designed in its hydraulic system to store the potential energy released during the elevator descending process and reuse it when it rises, so as to reduce the consumption of useless work and improve the efficiency of energy utilization, At the same time, the system can operate stably, reliably and safely.

For urban vehicles, frequent starting acceleration and braking are required. Low speed, high fuel consumption, serious emission pollution and noise are common problems of urban vehicles. The brake acts frequently, causing unnecessary consumption of energy. If the energy consumed by the brake can be recovered and released when the vehicle starts, it will undoubtedly be an effective way to improve the energy utilization rate and improve the vehicle emission performance.

For construction machinery, hydraulic equipment will produce great energy loss during operation. The use of accumulator can realize system energy saving, reduce energy loss and improve transmission efficiency. The function of the accumulator is: during braking, the pump/motor supplies oil to the accumulator as a pump, so that it can recover the braking energy and form the braking torque. The size of the braking torque can be controlled by changing the displacement of the pump/motor; During restart, the stored braking energy is released by the accumulator, and the wheels are separately driven by the pump/motor. When the machine reaches a certain speed after starting, it is driven by the engine; When the output power of the engine is greater than the power required to drive the wheels, the excess energy is input into the accumulator for storage; When the torque of the engine is less than the power required to drive the wheels, the accumulator releases energy to increase the torque of the driving wheels. The main advantage of accumulator is to absorb or supplement the output torque of the engine, so that the engine can always work under the working condition with the highest efficiency, recover and utilize the braking energy, and greatly reduce the fuel consumption caused by frequent starting and braking of the machine during driving.

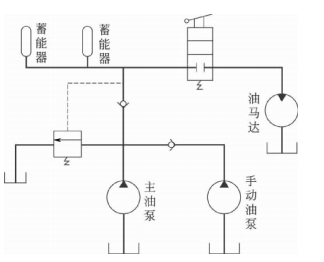

The picture shows the oil motor starting system of diesel engine, in which an accumulator is set. When starting, pull the two position two-way manual reversing valve, and the oil supply drive motor of the accumulator will drive the diesel engine to start. After the diesel engine is started, release the manual reversing valve to stop the circuit to the motor, and the oil pump will charge the accumulator for reuse. The manual oil pump in the figure is used to replenish oil after the accumulator leaks. Its riding comfort.