The No. 6 fan (AV80-14) in the power plant of a company is one of the key equipment for the production of blast furnace. It is an axial-flow electric blower with adjustable stationary blades. Suction air volume 5500 ³/ Min, outlet air pressure 0.45MPa, rotating speed 4410r/min, motor power 36140kw. The angle adjustment of the stationary blade and the opening of the vent valve are completed by a set of hydraulic system.

The power oil system is mainly composed of pump station, static blade adjusting valve group and vent valve group, with working pressure of 12.5MPa and maximum working flow of 59L/min.

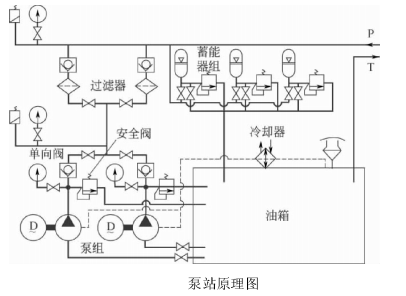

The pump station is mainly composed of pump unit (one for use and one for standby), overflow valve, accumulator, filter, oil tank, etc.

The pump unit adopts constant pressure variable pump, and the outlet oil pressure can be kept stable at 12.5MPa by adjusting its variable device. The set pressure of the overflow valve is 14MPa, which plays the role of overpressure protection. When the system pressure is lower than 11MPa, alarm and start the standby pump; when the pressure is lower than 9MPa, the unit shuts down. The filter can ensure that the system cleanliness meets the working requirements of the servo system. When the differential pressure of the filter exceeds 1.2MPa, an alarm will be given, and the operator will switch and replace the filter element.

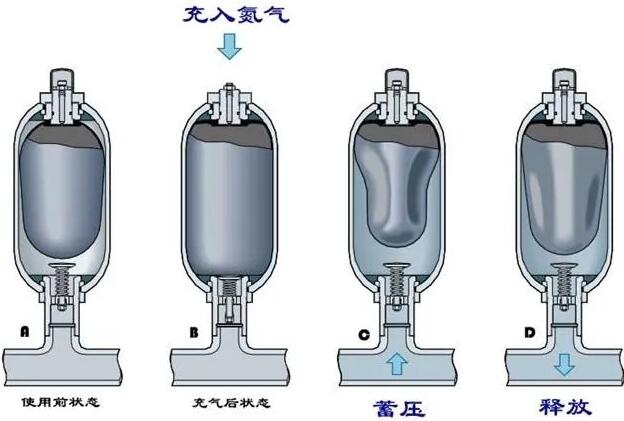

The accumulator plays a role in maintaining the pressure and supplementing the instantaneous flow of the system.

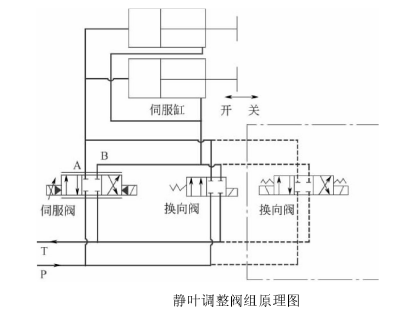

The static blade adjusting valve group is composed of MOOG72 servo valve and electromagnetic directional valve.

When the fan works normally, the servo valve controls the opening of the stationary blade (28 °~70 °) through the servo cylinder to meet the needs of various working conditions of the blast furnace. When the unit starts, it is required that the static blade release (14 °~28 °) be completed within 3s to ensure that the unit can quickly pass through the rotating stall area. In case of emergency shutdown of the unit, the electromagnetic reversing valve loses power and turns on oil to quickly close the stationary blade of the blower to 14 ° to ensure the safety of the unit.

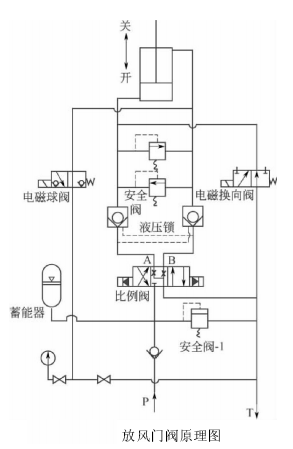

As one of the important protection means of the blower, the blower shall be opened with the function of slow closing and quick opening. The unit is equipped with two groups of automatic hydraulic blowers. Each group of control units consists of proportional valve, two position three-way solenoid valve, two position three-way solenoid valve, overflow valve, hydraulic lock, one-way valve, accumulator and other components.

When the blower unit works normally, the solenoid valve and solenoid ball valve are in a closed state, and the proportional valve is used to adjust the position of the control valve: in case of fault shutdown or countercurrent, the solenoid valve and solenoid ball valve are supplied with oil, so that the vent valve can be quickly opened for quick venting. Since the vent fan is far away from the pump station, an accumulator is added at the site to compensate for the loss of resistance along the way and keep the pressure constant. The set pressure of safety valve-1 is 13.5MPa to protect the valve group. The other two safety valves mainly prevent the impact of the oil cylinder.