The NXQ leather bag accumulator is taken as an example to explain the fault phenomena and troubleshooting methods of the accumulator. Other types of accumulators can be referred to.

(1) The pressure of the bladder accumulator drops seriously, and it often needs air supplement

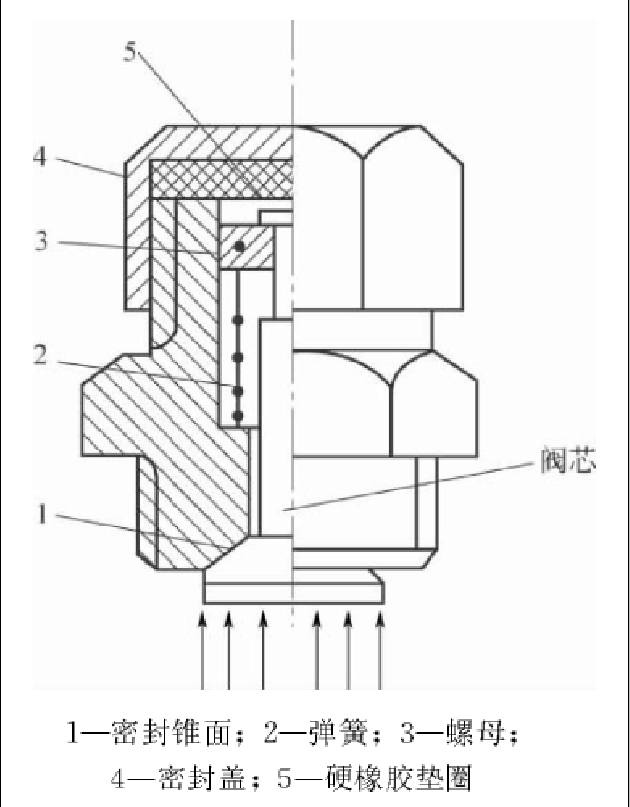

For bladder type accumulator, the charging valve of the bladder is a one-way valve, which is sealed by the sealing cone (as shown in the figure). When the accumulator is subject to vibration during operation, it may loosen the valve core, make the sealing cone 1 not close, and cause air leakage. The groove on the cone surface of the valve element or dirt on the cone surface may cause air leakage. At this time, hard rubber gasket 5 with a thickness of about 3mm can be placed in the sealing cover 4 of the charging valve, and measures such as grinding the sealing cone to make it close can be taken to solve the problem.

In addition, if the nut 3 on the upper end of the valve core is loose, or the spring 2 is broken or missing, the nitrogen in the leather bag may be exhausted immediately.

(2) Short service life of skin bag

The influencing factors are the quality of the skin bag, the compatibility of the working medium used and the material of the skin bag; Or dirt is mixed in; The nominal volume of m energy meter selected is inappropriate (the flow rate at the oil port cannot exceed 7m/s); The oil temperature is too high or too low; Whether the reciprocating frequency exceeds 1 time/10s when used for energy storage. If it exceeds the limit, the service life starts to decline. If it exceeds 1 time/3s, the service life drops sharply; Whether the installation is good and the piping design is reasonable.

In addition, in order to ensure that the accumulator can work reliably at the minimum working pressure, avoid the skin bag from colliding with the bacterial valve of the accumulator during the working process, and extend the service life of the skin bag, P ₀ should generally be selected within the range of 0.75~0.91; In order to avoid the excessive contraction and expansion of the skin bag during the working process, which will affect the service life, it is required to make P ₀ > 25% P ∈, that is, P ₁ > 33% P ∈.

(3) Accumulator does not work

The main causes are that the air valve leaks seriously, there is no nitrogen in the skin bag, and the skin bag is damaged and oil is fed. When the other P ₀ > P ∈, that is, the maximum working pressure is too low, the accumulator completely loses its energy storage function (no energy can be stored).

(4) Poor effect of absorbing pressure pulsation

In order to better play the role of the accumulator in absorbing the pulsating pressure, the connecting pipe between the accumulator and the branch point of the main pipeline should be short, the diameter should be appropriately larger, and it should be installed near the pulsating source. Otherwise, it will have poor effect in eliminating the pressure pulsation, and even aggravate the pressure pulsation.

(5) Poor stability of the flow released by the accumulator

Instantaneous wandering of accumulator charging and discharging liquid is a variable, especially in the system with large capacity and large ∆ P=P ∈ - P ₁ range, if you want to obtain a relatively constant and large instantaneous flow, you can use the following measures;

① Add flow control between the accumulator and the actuating element;

② Several accumulators with smaller capacity are used in parallel to replace a large capacity accumulator, and several accumulators with smaller capacity use different inflation pressures;

③ Reduce the working pressure range ∆ P as much as possible, or increase the structural volume (nominal volume) of the accumulator appropriately;

④ Sufficient liquid filling time shall be arranged in a working cycle to reduce the internal leakage of other parts of the system during liquid filling, so that the internal leakage of other parts of the system during liquid filling can be ensured to rapidly increase the pressure of the accumulator to P ∈ during liquid filling, and then release energy.

(6) Phenomenon of fuel tank injection

In actual operation, fuel injection from the oil tank is sometimes encountered. This is because the accumulator air bag is crushed under pressure, and a large number of bubbles enter the oil, which increases the compressibility of the oil. As the hydraulic pressure suddenly decreases from high pressure to low pressure, the oil flowing back to the oil tank expands rapidly in the tank. The pressure in the oil tank is higher than the atmospheric pressure, so that the oil and air are discharged from the vent hole together, resulting in fuel injection.

When the accumulator is suspected of failure, first check the nitrogen charging pressure of the accumulator.

In addition, if the nitrogen charging pressure is too high, there will also be an exception, because the oil stored in the accumulator is too small to meet the amount of oil used in the cylinder and cannot work normally.