In today's society, the number of motor vehicles in urban traffic is large, which brings huge energy consumption. Due to the concentration of urban population and vehicles, the operating conditions of urban vehicles are special. Especially for urban public transport vehicles, they need to start, accelerate, shift and brake frequently. High vehicle speed, high fuel consumption, serious emission pollution and noise are common problems of urban public transport vehicles.

The brake acts frequently, causing unnecessary consumption of energy. If the energy consumed by the brake can be recovered and released when the vehicle starts, it will undoubtedly be an effective way to improve the energy utilization rate, and also improve the emission performance of the vehicle.

As the hydraulic system with hydraulic accumulator has the characteristics of high energy density, controllability and reliability, it is very suitable for vehicles that require large energy in a short time during starting and braking.

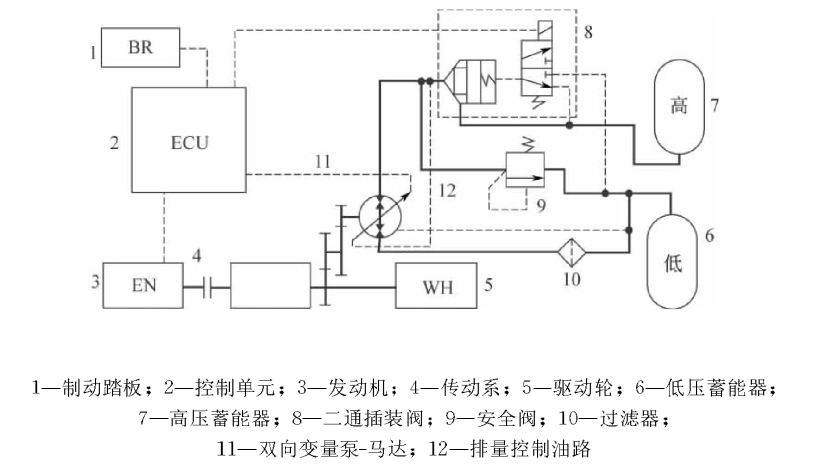

The vehicle has a certain amount of kinetic energy at the initial stage of braking. Under normal braking conditions, most of this energy is consumed by the brake in the form of friction, in addition to road resistance and wind resistance. In order to recover this kinetic energy, additional resistance sources are added to the vehicle transmission system to convert the dynamic energy into hydraulic energy for storage. The vehicle braking energy recovery system uses the two-way variable displacement pump motor as the energy conversion device and the leather bag accumulator as the energy storage unit. The system layout diagram is shown in the figure. When the vehicle is braking, the control unit 2 opens the two-way cartridge valve 8 according to the brake strength requirements of the brake pedal 1, so that the high-pressure accumulator 7 is connected with the high-pressure end of the two-way variable displacement pump motor 11, and also supplies the pump motor displacement to control the oil pressure, Operate the pump motor displacement in the positive direction to make it work as a pump. The kinetic energy of the vehicle drives the pump motor to rotate, acting as a source of resistance. At the same time, the low pressure hydraulic oil pressure is transferred into the hydraulic accumulator and converted into high pressure oil to achieve energy recovery and conversion. When the system is used as an auxiliary power source, the pump motor displacement is adjusted to the opposite direction, so that the high and low pressure oil ports remain unchanged and the rotation direction remains unchanged. At this time, the pump motor works as a motor. Open the two-way cartridge valve 8, and the high-pressure oil in the high-pressure accumulator 7 drives the pump motor to rotate, assisting the vehicle to start.