Using servo pump or variable speed pump to directly control the movement of differential hydraulic cylinder without throttling element is one of the effective ways to realize energy saving and reduce system heating in the field of hydraulic control technology, and is also a research hotspot at home and abroad at present. Develop the optimized loop principle to minimize the energy consumption while meeting the requirements of dynamic and static characteristics of the system. Based on this idea, in view of the characteristics of movement in the injection molding machine, use a single variable pump combined with an accumulator and a bypass proportional valve to control the loop principle of differential cylinder movement, which not only simplifies the system, but also reduces the energy consumption of the daily working cycle of the locking mechanism from 18 KW/S to 11 KW/S.

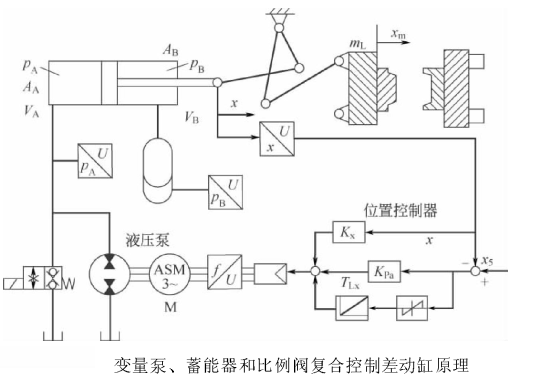

The circuit principle of the differential cylinder driven by variable displacement pump, proportional valve and accumulator to drive the mold locking mechanism of the rubber injection machine is shown in the figure.

The characteristic of the circuit is that when the piston rod of the hydraulic cylinder is extended, the hydraulic pump provides power, and the kinetic energy of the hydraulic cylinder movement is converted into pressure energy and stored in the high-pressure accumulator; When the piston rod retracts, the accumulator provides energy to the system. In order to eliminate the energy consumed when the motor is in the braking state in the return stroke, a proportional throttle valve is paralleled between the hydraulic pump and the oil tank. In this way, when the piston rod is recovered, the hydraulic pump stops working and the proportional throttle valve is used to control the speed of the cylinder. The circuit principle is applicable to both variable speed pump and the system composed of traditional servo pump. And only the hydraulic pump that works in one direction is needed. The glue injection machine has a long pressure maintaining and constant cooling cycle. The variable speed pump composed of servo motor and quantitative pump is selected as the power source to reduce the energy consumption of the motor in the cooling, pressure maintaining and other working cycles.